The East India Company at Dundaniel

In attempting to give an account of the East India Company at Dundaniel and especially their iron works, it has been necessary, in the absence of information, to study other Irish and English iron smelters for the same period and then try to reconstruct what must have taken place at Dundaniel. As the 300 settlers who came to Dundaniel were all English it would be reasonable to assume that they adopted the techniques of their own country when setting up a smelter at Dundaniel. Fortunately English iron working techniques for the late 16th and early 17th century are well documented and many of their ancient furnaces and ancillary buildings have survived, and been taken over -by the National Trust for preservation. What tittle information has survived on Dundaniel makes no reference to charcoal burning, but as such a practice was an integral part of early 17th century iron making, I have drawn the conclusion that it must have been practiced extensively in the woods around Dundaniel in support of their iron works. This paper gives the industrial techniques of the day in relation to iron making and charcoal production in order to broaden the reader’s concept of the settlement. In the case of William Burrell and the Dundaniel settlement I am indebted to Professor Michael McCarthy Morrogh who not only answered my questions but very generously loaned me his own researches on the settlement and gave full permission to quote from them. Without his contribution I his paper could not have been completed. I am also indebted to Tim Cadogan of the County Library who pointed me in the right direction on so many occasions and never failed to produce rare and out of print books on request. Last but by no means least I wish to thank Alan Roddie who kindly offered to share the burden and was solely responsible for ordering and deciphering of Calendar State papers from London.

CHAPTER I – WOODS

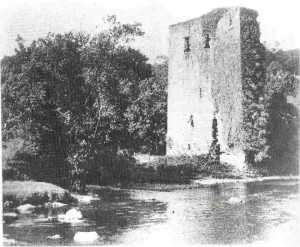

Dundaniel Castle, said to have been built by Barry Oge in 1476 was to become a nucleus for an East India settlement engaged in shipbuilding and iron making in the early 1600’s

During the 16th century England saw a rapid destruction of its forests for shipbuilding and charcoal production as a fuel to ironworks and blacksmiths. In 1558 a law was passed to prohibit the use of timber for charcoal making. This was never implemented and the practice continued on a relentless scale. By the early 17th century the shortage of timber in Britain was at crisis level. Blast furnaces developed over 150 years earlier had taken their toll in consuming enormous amounts of timber supplies. Forges also drew heavily on wood. The early 17th century saw Britain with no less than 85 blast furnaces, and all with an insatiable demand for wood. Britain needed plentiful supplies of timber for its navy and ships on which it depended so much, Ireland in contrast had abundant forests of top quality oaks and other hardwoods awaiting exploitation. An old tradition in Munster had it that a squirrel could start in Killarney and hop across the tree tops bough to bough all the way to Cork, so dense were our woods of oak and birch that when the English were marching to the siege of Dunboy in 1602 they were forced to detour around Kinsale and Timoleague. Irish oak was selected in 1630 to be felled in the Shillelagh Woods and used to roof Westminster Hall. The dominant trees on the landscape then were Oak, Ash, Birch and to a lesser extent Hazel, Holly and Willow. Conifers which are so common nowadays were not part of that landscape and the various Chestnuts and Maples were still regarded as exotics to be planted in the estates of country gentlemen in years to come. The British Navy selected great tracts of timber near waterways or within 10 miles of same as inland timber could not be transported or was too costly to transport. They built ships at Kinsale, Cork and Youghall using Irish oak. Coopering which was totally dependent on timber was carried on extensively in Munster in the 16th and 17th century and it was said that in those years Ireland casked nearly all the wines of France and Spain. The terms Butts, Pipes, Hogheads all referred to barrels of different capacity. Such barrels were also used extensively as food containers for such commodities as butter, meat, fish and tallow which formed the basis of the Irish export trade from the 17th century onwards. Barrel-Staves were exported in enormous quantities by Boyle, the Earl of Cork.

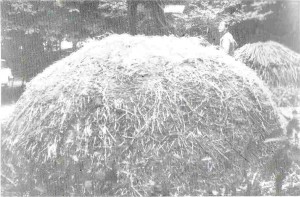

A reconstruction of as forest kiln in Sussex in 1972. Note the burner has used straw to bind the earth covering. These kilns were constructed on the spot where timber supplies were available

The oak forests around Bandon were to make the town famous for its tanning when it had five flourishing tan-yards in its heyday. Bark was stripped from the oak to be used in the tanning process. After the Plantation of Munster the new settlers flooding in to Ireland drew on native timber to make houses. Carpenters, wheel-rights, shoe-makers, mill-rights, turners and furniture-makers all drew on timber. Cooking fires in the settlers’ homes consumed the lesser pieces of timber. Whilst our early forests held out great hope of profit for the settlers they also had their drawbacks. They offered shelter to the dispossessed Irish known as “woodkerne”, as well as shelter to wolves who roamed the country. The Earl of Cork’s letters of the 1600, refer to wolves in the Bandon area. In 1720, Gougane Barra was referred to as a “Howling Wilderness of Wolves”. The British Navy had first refusal on the best specimens of timber available and as well as building ships locally they also exported plank and compass timber to England. Last but by no means least in demand for timber, were the charcoal burners who converted wood to charcoal fuel in great quantities. Charcoal is made by heating or charring wood out of contact with air. It was the smelting fuel of the bronze and iron ages as no other fuel then available could achieve the high temperatures required by our early metal workers. The conversion of wood to charcoal was a trade carried on by the “charcoal burner” and in most cases his family. These people would construct forest kilns on the spot with great skill and knowledge usually handed down from one generation to the next. Kilns were constructed in the forests themselves to avoid costly and difficult transport of the raw material. 100 tons of wood would produce 25 tons of charcoal. Level ground was necessary for the construction of a forest kiln and where this was not available the surfaces of sloping ground would be levelled in preparation. In siting a forest kiln advantage would also be taken of natural shelter from strong winds. Where shelter was not available temporary shelter of lattice or bracken would be erected. Near the kiln a crude hut or shanty would be erected by the burner with its door facing the kiln. From this hut the kiln operation had to be monitored night and day for the duration of the burn. Timber for charcoal production was usually cut into pieces 3 or 4 feet long and left to season for about 6 months. Heavy pieces would be split into thinner sections. In preparation for the burn timber was usually stacked to resemble a haystack. It was first covered with a combination of grass, straw, bracken and thin branches. The whole mound was then covered with earth, leaving a hole on top to start the fire burning.

Starting the burn. Shovelfuls of burning wood and charcoal are being poured into te chimney aperture at this demonstration at the Weald and Downland Open Air Museum in 1971.

When the fire became established sods would be used to plug the top hole and a series of new holes would be pierced around the stack at the discretion of the burner. Initially white vapour was produced as moisture was displaced. Later the smoke darkened and eventually turned a hazy blue. During the burn down, shrinkage would occur and cracks were liable to appear from time to time. These cracks would be sealed immediately by the attendant so that his work might not be ruined by unwanted air. An experienced charcoal burner would know by smoke and smell how his work was progressing. A useful by product of the kiln was tar which would be collected at the bottom of the hearth to be used later in conjunction with shipbuilding and caulking of planks. Charcoal burning was a seasonal operation and was carried out only in the summer months. In the winter the charcoal burners became woodcutters.

CHAPTER II – IRON

The structure of the Dundaniel Smelter would have been similar to the above structures with the typical two-arch arrangement. One arch housed the blowing machine, the other allowed iron to be run-off into sand beds at suitable intervals

In the early 1400s iron making was transformed by the invention of the blast furnace in Liege in France. This new furnace was rapidly to supersede the manually operated furnace which had been known to man for at least 4,000 years. The main ingredient of the new furnace was a “blast” of air from a powerful blowing machine. The blowing machine consisted of two sets of bellows arranged to blow alternatively and driven by cams on the shaft of a water wheel. The new blast furnace could now blow air relentlessly in huge volume, night and day without interruption, subject to a suitably harnessed river. Though the same fuel, charcoal, was used, it was now possible to attain much higher temperatures. Now for the first lime iron could be melted and run off the furnace as molten cast iron. This molten iron was run into depressions in a bed of sand and allowed to harden. These depressions in the sand and the channel that fed them resembled a comb in shape. A resemblance of the comb shape to a sow with its litter gave the name “pigs” to the cast iron ingots produced in this way, hence the expression “pig iron”. By this time coal was known mainly in the form of “sea coal”. This coal could not be used in iron making as impurities contained in the coal, especially sulphur had a deleterious effect on the process and resulted in an end product of brittle and useless iron. To make cannon, cannonballs, cooking pots and other utensils it was usual practice to first produce the desired shape in a box of sand or two half boxes which would be joined before casting. Pig iron ingots would be re-melted and poured into such sand-boxes and would eventually solidify to the desired shape. To make bar iron for swords and farm implements a different process, as well as a different furnace would be adopted. Pig iron ingots would be selected and heated to melting point in a “finery” furnace. Whilst in molten form the pool would be continuously stirred and prodded by the forge workers. This had the effect of driving off carbon and changing the chemistry of the mixture. Eventually the red hot liquid would become stodgy and take on a consistency of baker’s dough after enough carbon had been driven off. This red hot clump was known in the trade as a “bloom”. The bloom would then be delivered to the blacksmiths who further purified and reduced it to workable wrought iron by a series .of hammerings and re-heatings. Wrought iron was in great demand by shipbuilders to make anchors, chains and all the paraphernalia required in the masting and rigging of ships. The manufacture of wrought iron became totally extinct in the I870s. It tends to be fibrous in nature and fine example of wrought iron may be seen on viewing some of the ancient ships’ anchors at the back of the Kinsale Museum. As the furnaces of the 16th and 17th centuries were loaded from the top with charcoal fuel and Iron are to be converted, their builders tended to construct them against convenient hills. A short bridge would be constructed to link the top of the furnace with the hillside. This trend is evident at Dundaniel and the remains of an old smelter can be seen not more than 20 feet from a hillside. Charcoal and iron ore would be stored nearby in sheds to keep them dry. The furnace itself was made of stone and either squared or tapered in structure. The core of the furnace was lined in firebrick to cope with the high temperatures. Two arches were a characteristic of these early furnaces. One arch provided an opening for the pipe of the blowing machine, and the other allowed the iron workers to get near the core of the structure so that molten iron and slag could be run off at suitable intervals. As well as adding Iron ore and charcoal to the furnace the iron workers also added some limestone to the mixture after it had become molten. This had the effect of separating the impurity from the mixture and driving it to the surface where it could be skimmed off separately in the form of slag. The Dundaniel slag heaps, near the remains of an old smelter pot, are rich in cobalt blue and light brown glass. This is attributable to the presence of quartz either in the iron are at the time of melting or in the limestone. The high temperature of the furnace converted these quartz grains to molten glass which solidified on cooling. From its discovery in the 1400s the charcoal burning blast furnace remained unchanged in principle until the 1700s. Apart from dimensional differences from place to place all the indications are that this was the type of furnace to have been used at Dundaniel. Today there is little evidence of an East India Company presence on the site. However, a close inspection through the briars and underwood near the castle will reveal the remains of a smelter pot as well as heaps of ash and spent material from the furnace hearth. The slag-heaps are abundant with their colourful blue glass. The field to the west of the castle is strewn with fragments of iron debris kicked up from time to time by the hoofs of horses or cattle. Red fire brick is strewn on the river bed nearby. On the Brinny River near the Kilpatrick Railway Tunnel there are clear signs of an old earthen leet or mill race which would have been constructed to divert water to one or more waterwheels presumably to drive trip hammers used in the forging of bar-iron. Between 1600 and 1800 over 160 furnaces for iron making were known to have existed around Ireland. These furnaces could only be constructed where there was a natural combination of wood, iron are and water. We do not yet know where the Dundaniel settlers mined their iron but there is reference in the Calender State Papers to iron on the lands of John Roche and Lieut. Inquez of Bandon Bridge. In recent times local well drillers have reported on finding iron in the general area from Innishannon to Rising Sun and also plentiful traces of iron in BalIyheada near BalIinhassig. On the eastern bank of the Brinny River on the lands of Mr. Selka, there is a stream flowing out of the hillside which is heavily tainted with iron. This may be a clue to a local source of iron ore.

THE ENGLISH EAST INDIA COMPANY

The English East India Company was founded in 1600 by a consortium of London merchants under Royal Charter. Their objective was to engage in trade in the East Indies and Asia. The company survived for a period of 350 years. From humble beginnings it grew to enormous proportions very rapidly. By 1613 the East India Company had established two main trading stations, namely Surat in India to deal with Indian trade, and Bantam in Java to deal with South East Asia and the Far East. They began to build their own ships and by the year 1620 they had a fleet of 76 ships and had firmly established 12 trading stations in the East. They imported pepper. cloves, nutmeg, cinnamon and various spices, as well as indigo, raw silk from China, Indian calicos, cotton, sugar and saltpetre to make gunpowder. As well as importing goods they also traded from port to port in foreign waters, this aspect of their business was referred to as their “Country trade”. Of their varied imports pepper was the mainstay. The East India Company were now trading with such countries as India, Persia, Egypt, the Moluccas, Java, Siam, Borneo, Indonesia, Japan as well as ports on the China Sea. Many of their imported goods would again be re-exported from England to all parts of Europe, from ports on the Baltic to Venice on the Adriatic. Their outward bound ships were generally semi-empty except for provisions, but they did export woollens, tin, lead, quicksilver, iron goods and always vast quantities of silver bullion and to a lesser extent gold bullion to pay for purchases. They tried desperately to sell woollen goods to India and Persia but met with little success. One of their agents wrote from India to say that the Indians never bother to wear clothes even when the weather is cold and wet. The Company encountered fierce political and commercial rivalry from the Dutch and Portuguese. The Spanish were also enemies. To protect their interests they were compelled to provide fleets of fighting ships. They also erected forts in strategic locations and installed garrisons in same for their defence, They built their own ships on the Thames in London at two yards, Deptford and Blackwall employing over 500 men. They set up iron foundries at their London shipbuilding yards to make anchors and chains as well as nails and various iron implements. A spinning house was also provided for the making of cordage and sails. The docks contained a multitude of storehouses for timber, canvas and provisions. The Company also had its own slaughter house and always bought cattle on the hoof to be slaughtered by their own employees. Meat was preserved by pickling or salting and liberal amounts of beer were also included as an item of ships stores. It was company policy to feed their men well and they firmly believed that a well fed man worked better than one half-starved The stable diet on board East India Company’s ship, when the fresh provisions were exhausted, consisted of salted or pickled meat, usually beef or pork, bread or biscuits peas, beans, stockfish and beer, cider or wine for drinking. Sailors also consumed lemon water against scurvy. The scale of rations consisted of three loaves of bread per man per day, a pint of peas or beans, a pint wine and a quart of beer or cider. In addition to their shipbuilders, the indications are that in 1621 the company would have employed 2,500 mariners to handle their shipping fleet, plus agents around the world posted to the different trading stations. The East India Company was one of the biggest employers of labour in London at this time. They were granted permission by the London government to mint their own currency for their foreign purchases. On the negative side, the cost of shipping was always a high one, as ships wore out rapidly in tropical waters. A sudden storm, an error of navigation or a military engagement with the enemy could send many a ship to the bottom of the sea with its precious cargo homeward bound. Also, many of the company’s servants in the Indies and Far East traded dishonestly on their own account, well out of reach of their superiors back in London. In the 1620s however a prolonged famine in India which endured for six years and caused the great Indian depression had the effect of driving the company to near bankruptcy. One of their many drastic measures taken to survive was to implement 40% wage cuts to their staff. By 1630 the famine was over and their situation began to stabilize and recover.

The English East India Company was founded in 1600 by a consortium of London merchants under Royal Charter. Their objective was to engage in trade in the East Indies and Asia. The company survived for a period of 350 years. From humble beginnings it grew to enormous proportions very rapidly. By 1613 the East India Company had established two main trading stations, namely Surat in India to deal with Indian trade, and Bantam in Java to deal with South East Asia and the Far East. They began to build their own ships and by the year 1620 they had a fleet of 76 ships and had firmly established 12 trading stations in the East. They imported pepper. cloves, nutmeg, cinnamon and various spices, as well as indigo, raw silk from China, Indian calicos, cotton, sugar and saltpetre to make gunpowder. As well as importing goods they also traded from port to port in foreign waters, this aspect of their business was referred to as their “Country trade”. Of their varied imports pepper was the mainstay. The East India Company were now trading with such countries as India, Persia, Egypt, the Moluccas, Java, Siam, Borneo, Indonesia, Japan as well as ports on the China Sea. Many of their imported goods would again be re-exported from England to all parts of Europe, from ports on the Baltic to Venice on the Adriatic. Their outward bound ships were generally semi-empty except for provisions, but they did export woollens, tin, lead, quicksilver, iron goods and always vast quantities of silver bullion and to a lesser extent gold bullion to pay for purchases. They tried desperately to sell woollen goods to India and Persia but met with little success. One of their agents wrote from India to say that the Indians never bother to wear clothes even when the weather is cold and wet. The Company encountered fierce political and commercial rivalry from the Dutch and Portuguese. The Spanish were also enemies. To protect their interests they were compelled to provide fleets of fighting ships. They also erected forts in strategic locations and installed garrisons in same for their defence, They built their own ships on the Thames in London at two yards, Deptford and Blackwall employing over 500 men. They set up iron foundries at their London shipbuilding yards to make anchors and chains as well as nails and various iron implements. A spinning house was also provided for the making of cordage and sails. The docks contained a multitude of storehouses for timber, canvas and provisions. The Company also had its own slaughter house and always bought cattle on the hoof to be slaughtered by their own employees. Meat was preserved by pickling or salting and liberal amounts of beer were also included as an item of ships stores. It was company policy to feed their men well and they firmly believed that a well fed man worked better than one half-starved The stable diet on board East India Company’s ship, when the fresh provisions were exhausted, consisted of salted or pickled meat, usually beef or pork, bread or biscuits peas, beans, stockfish and beer, cider or wine for drinking. Sailors also consumed lemon water against scurvy. The scale of rations consisted of three loaves of bread per man per day, a pint of peas or beans, a pint wine and a quart of beer or cider. In addition to their shipbuilders, the indications are that in 1621 the company would have employed 2,500 mariners to handle their shipping fleet, plus agents around the world posted to the different trading stations. The East India Company was one of the biggest employers of labour in London at this time. They were granted permission by the London government to mint their own currency for their foreign purchases. On the negative side, the cost of shipping was always a high one, as ships wore out rapidly in tropical waters. A sudden storm, an error of navigation or a military engagement with the enemy could send many a ship to the bottom of the sea with its precious cargo homeward bound. Also, many of the company’s servants in the Indies and Far East traded dishonestly on their own account, well out of reach of their superiors back in London. In the 1620s however a prolonged famine in India which endured for six years and caused the great Indian depression had the effect of driving the company to near bankruptcy. One of their many drastic measures taken to survive was to implement 40% wage cuts to their staff. By 1630 the famine was over and their situation began to stabilize and recover.

One of the original members of this company was a William Burrell. He possessed a great deal of stock and for a number of years he sat on the ruling 24 man committee. Burrell’s primary profession was that of a shipwright and throughout the early 17th century he built ships for the East India Company from his yard in Deptford. One of his duties as a shipbuilder was to provide timber. Acting on his advice the East India Company bought and leased lands at Dundaniel on the Bandon River in the 1610s. A portion of those lands belonged to Sir Bernard Greenville whilst the second portion of land, including Dundaniel Castle, belonged to MacCarthy who was holding them for his nephew, a MacCarthy Reagh, who was a minor at the time. The lands purchased and leased would have been several thousand acres in extent. In the early 1600s MacCarthy had leased the same lands to a syndicate based in Cornwall who established an English settlement, presumably in Kilpatrick, to engage in cutting and exporting timber. This venture was managed locally by a William Carnsew. The enterprise did not prosper and the Cornish men withdrew from the area shortly before Burrell and the East India Company arrived. They might well have handed over the place to Burrell on his arrival. The Carnsew family still retained wood rights in the Dundaniel area up to 16!1 and also employed agents to export wood from other parts of Ireland. The objectives of the East India Company at Dundaniel were to establish an iron works and a ship building yard. The prime pieces of timber would be cut and selected for shipbuilding, while the lesser or waste pieces would be used to fuel their furnace having first been converted to charcoal fuel. Originally the company intended to build all its new ships in Dundaniel, but by the year 1615 this decision had been reversed. The reason given was that Burrell would not be able to supervise the work directly. The operation was manned by 300 English settlers whose total wage bill amounted to £40 per week. To house them three towns were built. The largest was “Thomas” on the lands of Kilpatrick. A second town called “The Hope” was located near their ironworks at Dundaniel and a third town known as “Bantam” was built on their shipbuilding dock. To defend their settlement “for fear of Ye Wylde Irish” they stocked Dundaniel Castle with provisions and installed a fighting force said to be constantly maintained in a “Warlike Manner”. This fighting force consisted of six lightly armoured horse soldiers, six foot soldiers and ten musketeers. The towns of Thomas and Hope may have been named after two ships of the East India Company bearing the same name. Thomas and Hope may have been the very ships of 500 and 600 ton burden said to have been completed at Dundaniel in the year 1613. Bantam was an East India trading post in Java and may have prompted the name of the third town on the dock. The settlers built dams and weirs on the Bandon and Brinny rivers to provide waterpower to drive their machinery. They built a bridge across the river to transport their timber and complained about having to bear the cost of same. They maintained that the bridge should have been provided by the country. They constructed a dock to build ships and erected warehouses, sheds, forges and a blast furnace to the west of Dundaniel Castle. In conjunction with felling timber for their own consumption they also exported timber and barrel staves on a continuous basis up to 1620 and occasionally up to 1630. By the year 1617 they were looking around Munster for new Sources of timber. This might indicate that local supplies were running out. State papers refer to ships being built at Dundanie. In view of the shallow water in this area it would be impossible to launch such ships. It is much more likely that the shipbuilding dock was in the region of Kilmacsimon Quay as well as the town of Bantam. A few hundred yards down river from Kilmacsimon there is an ancient deep-water dock. However, no evidence has come to light to link it with the East India Company. The settlement seems to have established itself with amazing speed. By October 1610 the first ship of four to five hundred tons burden was being built and by late l611 had been launched and was reported to be in the East Indies. By the year 1613 the purchase and leasing of the lands, as well as the building and equipping of the venture had cost the East India Company £7,000. One portion of the lands consisted of three plough-lands containing 1,250 acres which included the lands or Kilpatrick. Burrell had settled this section with 11 under-tenants, each with a house and an average of 20 acres. Also there were 39 tenements. Fifteen of those had an acre and the remainder had gardens, Indications are that this was the town of Thomas known more commonly as Kilpatrick. The speed at which Burrell settled his tenants would suggest that some members of the earlier Cornish venture had remained on to act as a nucleus for the new group. After a good start the East India Company encountered local opposition from more than one source. Their efforts were opposed by the local Irish led by their champion Waiter Coppinger. They were also opposed by the High Sheriff of Cork, Peregrine Bannister. McCarthy began to dispute the lease arrangements he had previously made with Burrell, and finally the Great Earl of Cork, Lord Boyle, had his own complaints to make. For the locals the issues at stake were the dams and weirs built by the company on both rivers for their iron works. These dams hindered the passage of fish, especially salmon, and were also’ said to effect river transport. Coppinger opened the campaign in l615 with a sheaf of indictments against the company’s dams on the Brinny River. The East India Company petitioned the Privy Council to restrain Coppinger and whilst successful, they were still compelled to modify the dams to facilitate the passage of fish. This action partly subdued the locals who originally wanted all dams and weirs removed. In 1619 the offensive was renewed. This time Peregrine Bannister, the High Sheriff of Cork appeared to be in a very violent mood when he threatened to march on Dundaniel with a hundred men to “Pluck Down” the weirs and dams, Again the East India Company petitioned London for restraint. The Privy Council of London seems to have favoured their requests as the weirs were still on the Bandon River in 1630 and still provoking disputes. As well as the Dundaniel venture, William Burrell had other business interests in Munster. Burrell and an accomplice Mr Ball seem to have shared a lease with Lord Boyle and were involved in some way in Boyle’s Iron Works at Tallow near Cappoquin. However a dispute arose when Boyle claimed that Burrell and his associate ran down his Tallow Iron Works in order to enhance their operation at Dundaniel. Boyle claimed to be owed substantial sums of money by Burrell and Ball and proceeded to issue suits accordingly. Boyle petitioned that his case be tried in Youghal and not in London in view of the hazards of sea travel in winter time. Perhaps the Dundaniel Iron Works was an unwelcome competitor to Boyle’s own iron works at Tullow, in the 1620s Boyle acquired the lands of Sir Bernard Greenville and thus became Burrell’s landlord. Boyle was now m a position to make things uncomfortable for Burrell and his English settlers at Dundaniel and it would be reasonable to assume that he made attempts to contribute to its decline. Another factor may have been dwindling timber resources. In any case, by the year 1641 the Iron works was described as old and decayed.

ACKNOWLEDGEMENTS

- Professor Michael McCarthy Morrogh

- Mr. Tim Cadogan

- Mr. Alan Roddie

- The County Library

- U.C.C. Library

- Calender of State Papers Ireland and Domestic

- The English East India Company, K.N. Chaudhuri

- House of Lords Manuscripts

- The British Library

- The India Office Library

- The Coalbrookdale Museum of Iron

- Blist Hill Iron Works

- Mr. Phil Bond, Irish Steel Holdings

- Weald and Downland open air museum (who kindly gave permission to print photos relating to charcoal burning.)

- The Curator H.M. Tower Of London

- Irish Woods since the Tudor limes Eileen McCracken

- Mrs. Daisy Loane, Dundaniel

- Mr. Billy Connell

- Shire Publications

Paddy O’Sullivan